Continuous PU Sandwich Panel Line

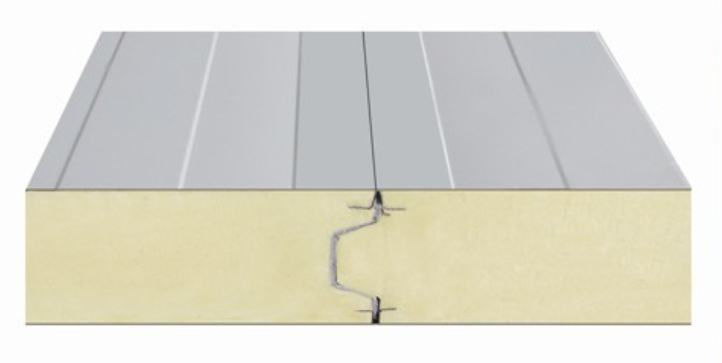

PU sandwich panel is the new wall building materials which have the best function of heat preservation, heat insulation, sound insulation, fire retardant, water proof, portable, environmental protection etc. It can be widely used in the external wall of retaining and decoration of high-rise building and senior office building The PU sandwich panel is the new wall building material for retaining, decoration and heat preservation. It is the most popular of new generation of decorative wall retaining timber construction. The product of this line—PU sandwich panel, is produced with foaming at working site. There’s device which can inject the foaming material between the upper and lower metal sheet ,then will be sent into double belt and evenly forwarded. The chemosynthesis and solidification are finished inside of double belt. The cutting is finished according to the length which is set before running the machine, it is non-stop cutting type, and the cutter will be moved along with the panel.

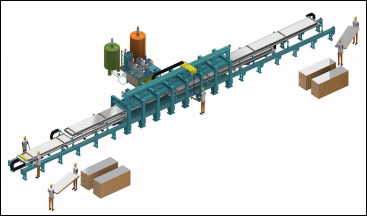

Decoiler-------Film covering (flat plate cutting) ------Roll forming-------Preheating material-------PU Foaming------Laminating in double belt conveyor (heat preservation)-------Band cutting(dust absorption)------Fast table roller------Panel cooling------Stacking(turning board)-------packing

Sandwich Panel Spec. Length Min. cutting length 2 m; Max. stacking length 15m Wall panel width 1000mm(according to profile requirement) Wall panel thickness 50/75mm (Max.200mm)(see attached profiles for details) Steel Sheet Specs Color sheet thickness: 0.4-0.8mm(Sheets should be flat without bumps, distortion and side bending.) Sheet yield strength: 235MPa(Max.300MPa) Coil width 10T Max. sheet width 1250mm(width tolerance up to ±2mm) Inner Diameter of coil Φ508 or Φ610 mm Foaming material: POL and ISO, pentane foaming agent PU forming density 36~45 kg/m3 Whole Line Specs Working speed 3-7m/min (adjustable) Total length about 130m Working height 1200mm (height of panel coming out) Foaming working pressure: 150-200bar Effective length of double belt conveyor 30m Control mode imported PLC system Total power about 250kw(excluding electric heating power 380kw) Power required 380V/3phase/50Hz Control voltage 24V / 220v Air pressure 0.7Mpa (prepared by buyer)

|

No. |

Name |

Components |

Unit |

Qty. |

Remark |

|

1 |

Decoiler |

Decoiler(10T) |

set |

2 |

|

|

Coil car(10T) |

set |

2 |

|

||

|

Sensor |

set |

2 |

|

||

|

Arc pinch roller table |

set |

1 |

|

||

|

Hydraulic system |

set |

2 |

|

||

|

2 |

Filming Cutting |

Upper filming cutting device |

set |

1 |

|

|

Lower filming cutting device |

set |

1 |

|

||

|

Edge slitting device |

set |

2 |

|

||

|

Recoiling device |

set |

2 |

|

||

|

Sensor |

set |

2 |

|

||

|

3 |

Roll forming |

Upper roll former(1 plate) |

set |

1 |

Through-shaft type roll former 1 set |

|

Lower roll former(1 plate) |

set |

1 |

Through-shaft type roll former 1 set |

||

|

Upper roll former support platform |

set |

1 |

|

||

|

Upper and lower interface roller table |

set |

1 |

|

||

|

4 |

Heating |

Double-layer steel preheating |

set |

1 |

Electric heating |

|

Double belt heating |

set |

1 |

Electric heating |

||

|

5 |

Foaming system |

3-component pentane high pressure foamer |

set |

1 |

|

|

6 |

Foaming system accessories |

Horizontal roller table |

set |

1 |

|

|

Upper and lower guiding device |

set |

2 |

|

||

|

Tape and sponge device |

set |

1 |

|

||

|

7 |

Double belt |

Double belt machine |

set |

1 |

|

|

Side belts |

set |

1 |

|||

|

Side mould |

set |

1 |

|||

|

Hydraulic system |

set |

1 |

|||

|

8 |

Band saw cutting |

Turnover roller table |

set |

1 |

Servo control |

|

Cutter |

set |

1 |

|||

|

Retractable roller table |

set |

1 |

|||

|

Fast roller table |

set |

1 |

|||

|

Output roller table |

set |

1 |

|||

|

Disc saw cutting device |

set |

1 |

|||

|

Band saw dust-cleaning device |

set |

1 |

|||

|

9 |

Cooling device |

Cooling conveyor |

set |

1 |

|

|

Cooling front and rear roller table |

set |

1 |

15m long |

||

|

10 |

Stacker |

Output roller table |

set |

1 |

15m long |

|

Turnover device |

set |

1 |

|

||

|

Gantry frame |

set |

1 |

|

||

|

Sucking device |

set |

1 |

|

||

|

Hydraulic system |

set |

1 |

|

||

|

11 |

Packing machine |

Horizontal packing machine |

set |

1 |

|

|

Conveyance roller table after packing |

set |

1 |

Length 15m |

||

|

12 |

Electric control |

Electric control system |

set |

1 |

Fill out the form to contact us, We promise to respond to you quickly.