Aluminum Cut to Length Line

This line is suitable for aluminum coil decoiling,sheet leveling, cross cutting to the length according to the customer’s request ,palletizing of steel plates and finally it is packed into a whole bundle of flat plates according to the need.

The expected life of the machine usage is ≥20years

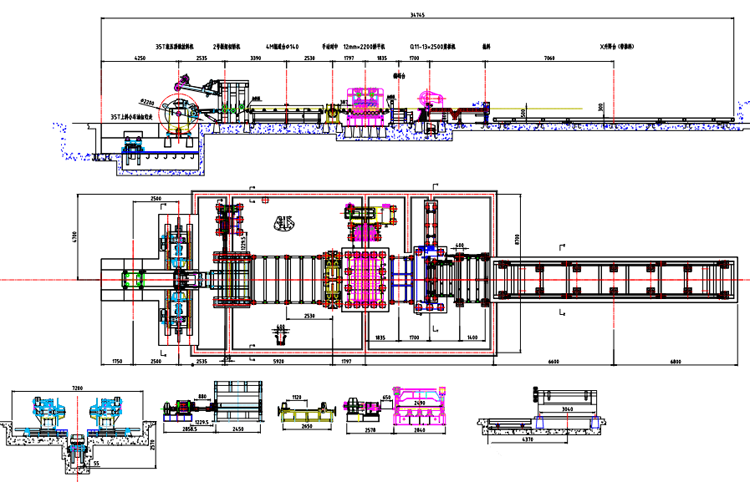

Coil loading car----Decoiler----coil head press, guide and shovel equipment----Double pinch rollers---Centre aligner----high-precision levelers( 23 rolls)---encoder ----hydraulic tracking cutting machine--pinch rolls for sheets dropping-- plates-delivering roll table----plates sending out device----plates supporting table---plates piling up device--manual packingr

|

Item |

material thickness/mm |

Material width |

speed/mpm |

|

1 |

0.2-2 |

400-2000 |

0-50-80-100-150 |

|

2 |

0.3-3 |

400-2000 |

0-50-80-100-120 |

|

3 |

0.4-4 |

500-2500 |

0-50-80-100-120 |

|

4 |

0.5-5 |

500-2500 |

0-50-80-100-120 |

|

5 |

1.0-6 |

500-2500 |

0-50-80-100 |

|

6 |

2.0-8 |

500-2500 |

0-30-50 |

|

7 |

3.0-10 |

800-2500 |

0-30-50 |

|

8 |

4.0-12 |

800-2500 |

0-30-50 |

|

9 |

8-16 |

800-2500 |

0-30-50 |

|

10 |

6.0-20 |

800-2500 |

0-30 |

|

item |

specifications |

|

|

Raw materials |

Materials feature |

Aluminum alloy 3003 and 5052 |

|

thickness |

0.5mm—3.0mm |

|

|

Aluminum feature |

Tensile grade σb≤450MP Yield grade σs≤260MP |

|

|

width |

800mm—1300mm |

|

|

O.D |

Φ800mm—φ2100mm |

|

|

I.D |

φ508mm—φ610mm |

|

|

Coil weight |

Max 15T |

|

|

Finished product |

Flatness without any increased processment faults |

|

|

Cutting length |

500mm—4000mm |

|

|

Leveling precision |

less than 25% raw materials non-flatness(1.5-2mm/㎡) |

|

|

Cutting tolerance:

|

±0.5mm/1000mm( length tolerance) ±0.50mm/1000mm( diagonal tolerance) Match the standard GB/T709-88 |

|

|

Strip threading speed |

0—10m/min |

|

|

Line speed |

0-20m/min |

|

|

Cutting speed |

0-15 pcs/ according to the length 2000mm |

|

|

Total line power consumption |

About 130kw |

|

|

Center line of the line ( to the ground) |

800mm |

|

|

Space of the whole line |

18mx9m |

|

|

Line direction |

Left input to right output or right to left direction |

|

Power supply conditions: 3 ph, AC, 415V+10%, 50Hz+2%

Air source: compressed air:

pressure: 0.5-0.6 MPa

displacement: 1.5 m3/min

Water source: no requirement

Environmental Conditions in Factory Buildings :

Temperature - 5 ~40

Relative humidity < 90% (without condensation)

|

item |

N/m |

Qty |

power(KW) |

description |

|

|

|

|

|

DC |

AC |

|

|

1 |

decoiler |

1 |

18.5KW |

|

main drive and back-tensioning |

|

2 |

Pinch roll |

1 |

|

5.5KW |

Main drive |

|

3 |

Leveling machine |

1 |

45KW |

|

motor |

|

4 |

Film covering machine |

|

|

1.5KW |

|

|

5 |

Pneumatic cutting machine |

1 |

|

7.5KW |

Main drive |

|

6 |

Servo-motor |

1 |

|

22kw servo-motor |

Servo motor control |

|

7 |

Hydraulic station |

1 |

|

7.5KW |

Oil pump control |

|

Total |

About 130KW |

|

|||

Fill out the form to contact us, We promise to respond to you quickly.