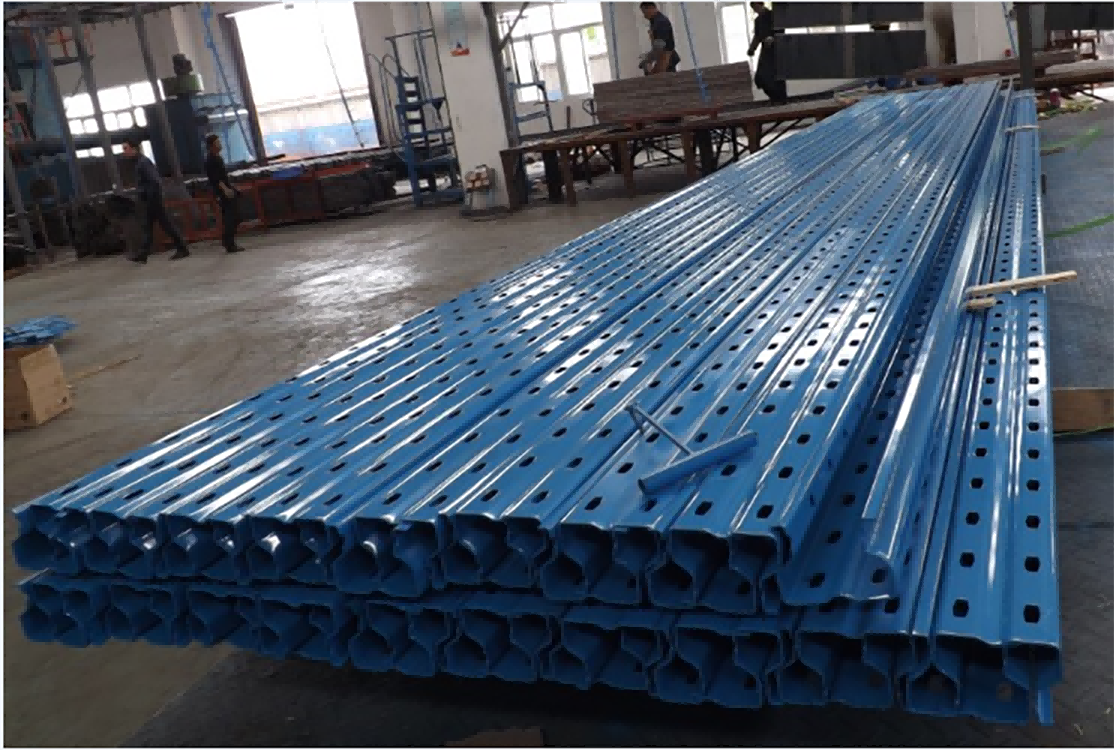

Pallet Rack Roll Forming Machine

Rack roll forming machine is made from hot rolled steel strips,rack roll forming machine staightended,holes punched,roll formed,and cut to length by the rack roll forming machine. the finished products are of many features,such as high efficiency,high automatization,less labor,and etc.

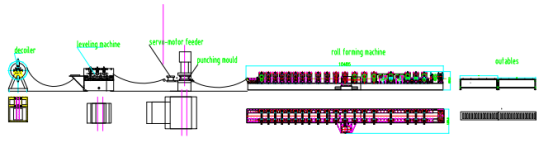

Hydraulic de-coiler-Powered leveling –Servo feeding-Hole punching- Forming-Hydraulic cutting-Output table

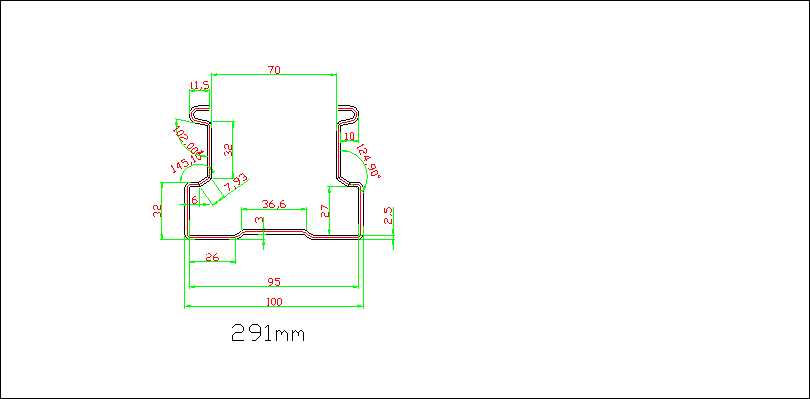

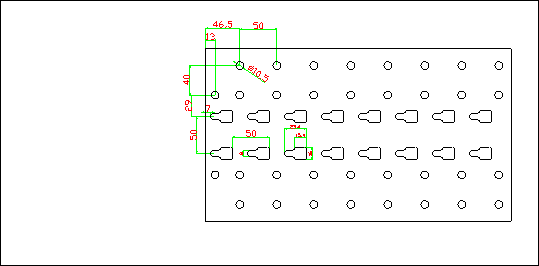

1.Finished products:76/102/127x70 racks with holes punching 2.Raw material request: galvanized steel 3.Material thickness:1.2mm-2mm 4.Whole line working speed:>3--5m/min 5.Cutting Error: ≤±2mm 6.Floor Space:30*2*3m 7.Pressure:380V,50Hz

|

Item |

Components Name |

Quantity |

|

1 |

3T hydraulic Decoiler |

1 set |

|

2 |

Leveling machine |

1 set |

|

3 |

80T punching press |

1 set |

|

4 |

Punching mould |

4 sets |

|

5 |

Quick -changeable Roll Forming Machine |

1set |

|

6 |

Flying shear |

1 set |

|

7 |

Hydraulic Station |

1set |

|

8 |

PLC control cabinet |

1set |

|

9 |

C beam combination machine |

1 set |

|

10 |

Outables |

2 pcs |

|

11 |

Cutting blade |

4sets |

Fill out the form to contact us, We promise to respond to you quickly.